Product introduction

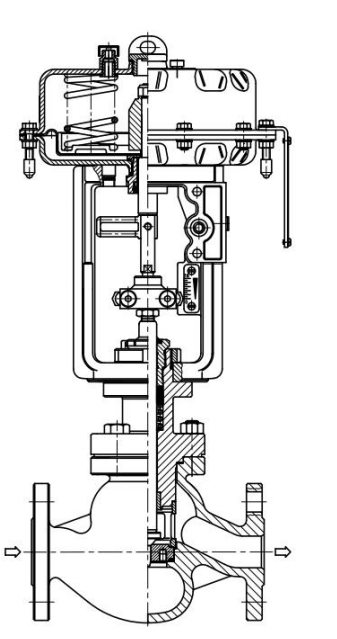

The CAU single seat control valve has a compact structure and is one of the basic products of the C series high-performance control valves. Easy to maintain, quick change, direct pressure type valve trim self centering design, with excellent sealing performance. Parabolic cylinder valve core structure can ensure wide adjustable range, high accuracy of flow characteristic curve and realize micro flow control.

The compact structure of CAU single seat regulating valve is widely used in many fields. Because the valve core will not be stuck, it is especially suitable for controlling the fluid containing particulate impurities and for applications where the temperature changes greatly.

The regulating valve is equipped with DA series multi spring pneumatic membrane actuator, which has a firm and compact structure, novel and beautiful appearance, and excellent performance. The high-strength diaphragm can withstand the air supply pressure of Max0.6MPa, making the output force of the actuator strong, thus ensuring the smooth operation and tight closing of the control valve. In addition, the actuator has extremely high versatility and interchangeability. As long as the membrane head is turned over on site, the action form can be easily changed.

The positioner supplies air to the actuator through the hole in the bracket, and there is no special external air source pipe. Compared with the traditional design, this design improves the reliability and vibration resistance of the actuator, reduces the space occupied by the control valve, and simplifies the assembly process of the positioner. The clean gas discharged by the positioner makes the spring chamber always maintain positive pressure against the external atmosphere. During operation, the external gas will not be sucked into the spring chamber, so as to protect the foundation internals from being eroded by harsh environment (such as acid, marine climate, etc.), and double the use of auxiliary energy.

technical parameter

Nominal diameter: DN15-400

Nominal pressure: ANSI CL150, 300, 600

DIN PN16、25、40、63、100

JIS 10K、20K、30K、40k

GB PN1.6、2.5、4.0 、6.4、10.0 MPa

Connection mode: flange type ANSI B16.5 RF, RTJ

DIN2543/2544/2545 RF

GB/T9113 RF、FM

Welding type ANSI B16.5

Fillet weld SW

Upper bonnet type: standard type...... - 46 ~ 200 ℃; 200℃~300℃

Heat sink type............ 300 ℃~ 530 ℃

Valve core form: parabolic cylinder valve core

Flow characteristics: metal valve seat:

Equal percentage CV: 0.25 ~ 2925

Linear CV: 0.01 ~ 2925

Soft seat:

Equal percentage CV: 0.25 ~ 2925

Linear CV: 0.1 ~ 2925

Actuator type: DA series multi spring membrane type

Spring range: 50-300Kpa

Air supply pressure: max. 6bar

Air source interface: G1/8 (DA1/DA2), G1/4 (DA3/DA4), G3/4 (DA5)

Ambient temperature: - 20 ℃~+80 ℃

Optional accessories: positioner, filter pressure reducing valve, solenoid valve, limit switch, valve position transmitter, handwheel mechanism, quick exhaust valve, speed control valve, pneumatic retaining valve, etc

Remarkable features:

▲ Valve seat can be used on both sides to improve service life

▲ Multiple materials available

▲ Quick installation and disassembly without special tools

▲ Maintenance free packing

▲ High cost performance

▲ Wear resistant and corrosion resistant stuffing box.